Strategies

Efforts to miniaturize heat exchangers

Microchannel heat exchanger

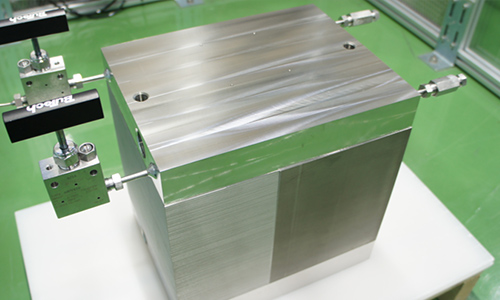

The micro channel, embedded in our heat exchangers, consists of micrometer-order flow paths like capillary blood vessels. Micro channel heat exchangers are characterized by high efficiency of heat exchanging due to very close distance between high-temperature fluid and lower one. Normally, it would be difficult to exchange heat in the vicinity while maintaining the withstand voltage performance of the heat exchanger, however, it can be realized by our micro channel heat exchanger.

A heat exchanger could be smaller by embedding micro channel in it without degrading its heat exchange performance compared to the one that does not have micro channel. In addition, by reducing the size, it could be possible to harness the flow rate.

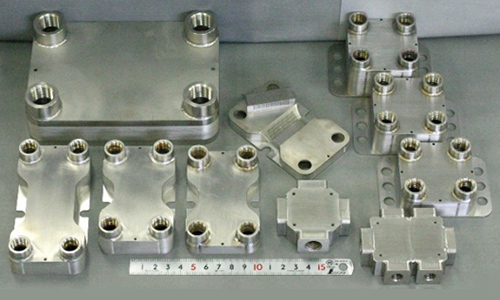

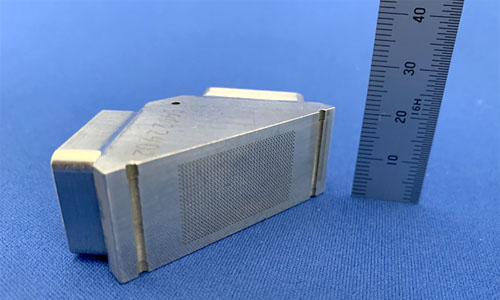

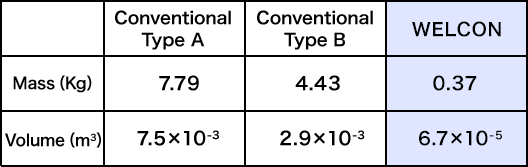

WELCON realized smaller heat exhcanger to 1/100 size by cubic volume while maintaining the almost same exchange performance.

The following is an example of size comparison of heat exchangers with similar performance.

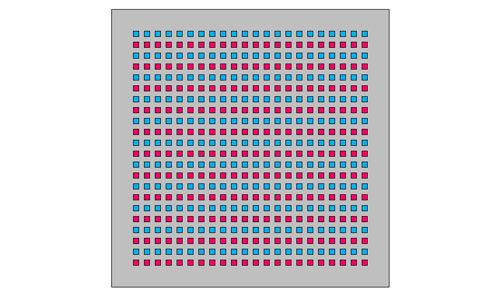

Increase in heat transfer area due to microchannelization

By reducing the flow path diameter (microchannel), the number of flow paths can be increased and the heat transfer area can be increased.

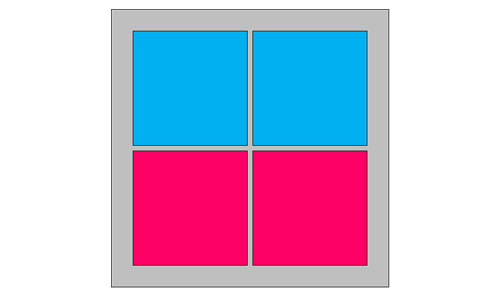

The following is an example of comparing the heat transfer area of a normal heat exchanger and a microchannel heat exchanger. In the case of this example, microchannelization increases the heat transfer area by about 6 times.

□ 5mm flow path

□ 5mm flow path

2 × 2

Heat transfer area = 5 x 4 x 2 ^ 2 = 80 mm²

□ 0.25mm flow path

□ 0.25mm flow path

22 × 22

Heat transfer area = 0.25 x 4 x 22 ^ 2 = 484 mm²

Realizing features of high corrosion and heat resistance by fabrication based on solid state diffusion bonding

Solid state diffusion bonding is a method of directly jointing materials and different from the methods of welding and brazing.

Since it is composed only of the base material, it could achieve higher resistance of corrosion, heat, and pressure compared to other jointing methods.

The following is the pressure resistance test of the heat exchanger (named WEL-Cool H2C) built in hydrogen supply dispenser. We have passed the inspections such as "1 million-times repeated pressure resistance tests under 100MPa" and "4x pressure resistance test (400MPa)" which are required for certification acquisition.

Our pressure resistance test equipment (design upper limit)

- Pressure-resistant confidential test equipment (125MPa)

- Pressure-resistant water pressure test equipment (480MPa)

- Repeated pressure resistance fatigue test equipment (150MPa)

Liquid Cool Micro Channel Heatsink

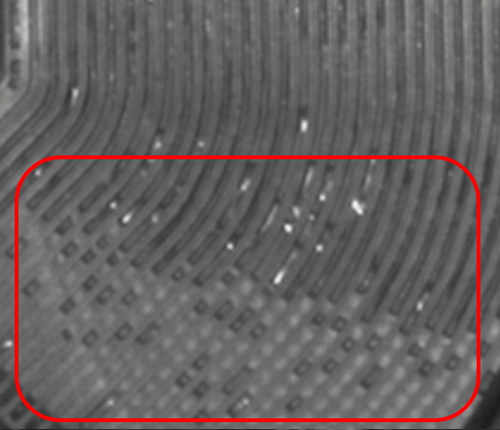

Achieves uniform cooling by the matrix-like flow path

We are good at optimizing the internal three-dimentional structure with micro channels. Heat sinks with microchannels have not only high cooling performance, but also unique fluid distribution. For example, matrix-like channel structure is implemented to supress temperature bias in cooling area and cosequently to perform uniform cooling there.

One example of WELCON's heat sink is achieved to suppress the temperature rise within 40 ℃ against the heat source that generates about 260W / ㎠. If with the existing one-channel heat sink of the same size, the temperature rise would exceed by 200 ℃. It seems to be difficult to achieve sufficient cooling performance.

Efforts for heat dissipation technology

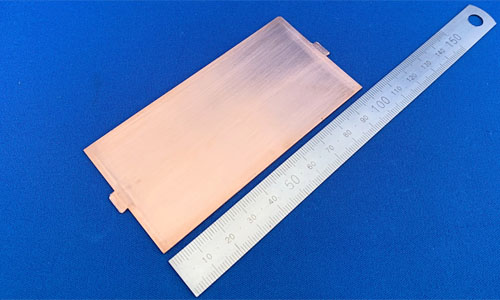

Efforts for development for much thinner heat pipe; vapor chamber

A heat pipe is a device to enhance heat transfer and spread from its source. One of the drawbacks of conventional heat pipes is that it could lack contact area with heat source due to its rod-shaped design, which causes performance degradation. Closer contact needs "flattening" and the design is achieve by "vaper chamber".

WELCON's vapor chamber

WELCON's vapor chamber

Conventional heat pipe

Conventional heat pipe

The feature of WELCON's vapor chamber is that it has flat surface shape to be close contact with the heat source. Also, it can be bent, and placed in a three-dimensional space.

The characteristics of WELCON's vapor chamber are its "thinness" and "high thermal conductivity".

- Achieves high thermal conductivity even in an unfavorable posture (ex; top heat status).

- Can be used even when the heat source is about 100 ℃ or more.

- There are many development achievements. Much thinner than a 1-yen coin can be realized.

We will respond to consultations from scratch, such as examining the shape that fits customer's request and performance according to the usage environment.

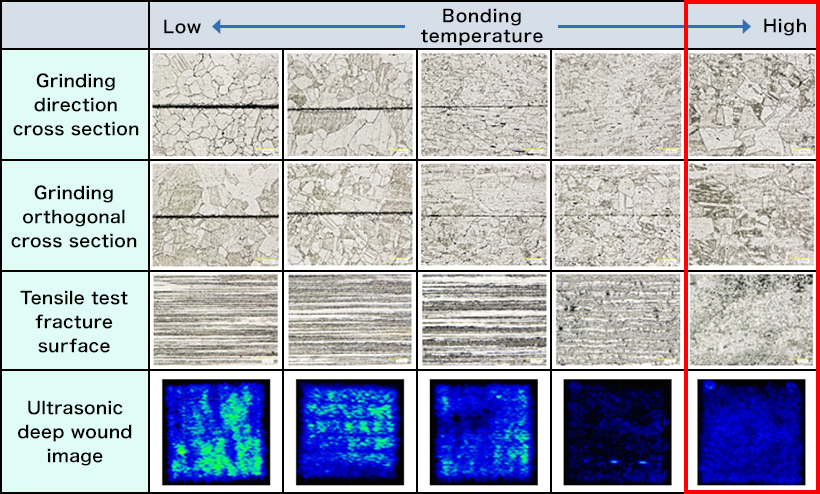

Diffusion bonding; Efforts for improving reliability

We have equipments, know-hows, and data accumulation to prove the quality of our products manufactured by diffusion bonding.

Here is an example;

Bonding interface, tensile test, and ultrasonic image are shown above at 5 patterns of bonding temperature.

At the highest bonding temperature, the bonding boundary disappears, which indicates that the two materials are united in the atomic level.

Fluid analysis technology

We place the importance of not only simulation but actual observation and experimentation of how the fluid flows in the products. The photo shows flow-observation of two phases as gas and liquid. Such experimental results are effectively exploited for further studying and designing novel structures and features.