Core

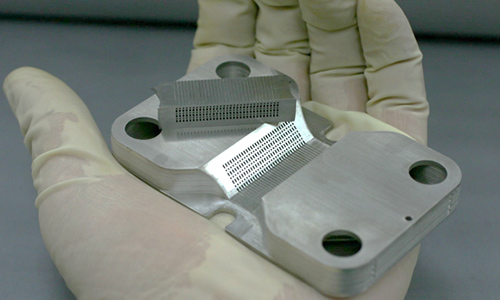

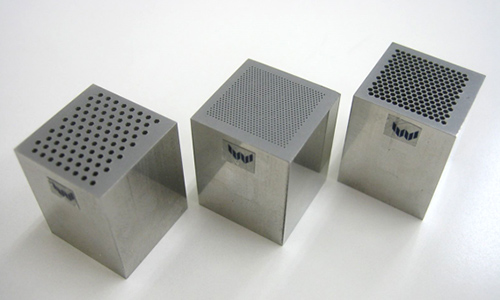

Realization of microchannel structure

The metal plates can be precisely superimposed. This makes it possible to realize microchannels structures.

For example, 300 plates with honeycomb hole structures,whose size are from 250µm to 800µm, are accuratly stacked without any hole dislocation, and the holes can be penetrated.

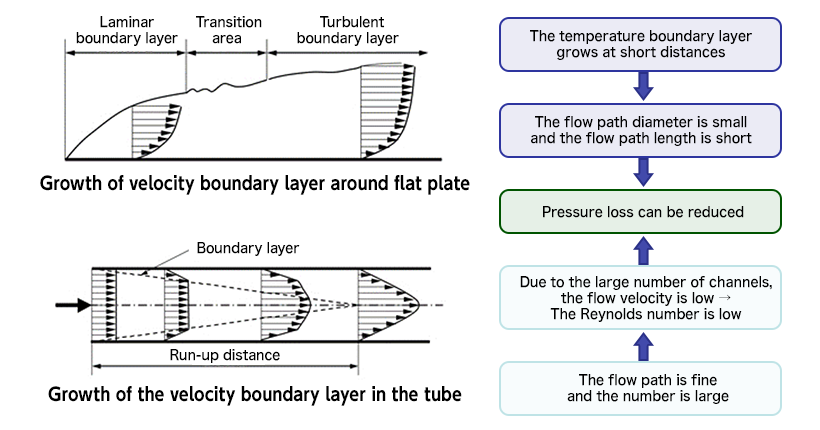

About pressure loss

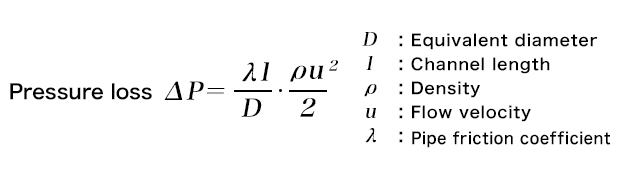

Pressure loss is the energy loss caused by the friction coefficient of the wall as the fluid flows along the inner wall of the pipe.

The pressure loss doesn't increase uniformly and proportionally with microchannelization. It can be controlled by the channel design of the product.

The pressure loss (ΔP) depends on the microchannel diameter (D) and channel length (l), with P inversely proportional to D and proportional to l.

The other parameters are physical quantities that depend on the fluid.

Microchannelization contributes to the reduction of both diameter and channel length. By controlling the degree of convergence of both parameters, the overall pressure loss can also be controlled.

At the same time, it contributes to increasing the number of parallel channels. If the flow rate is constant, the pressure loss can also be controlled by controlling the number of parallel channels and the flow rate.

Depending on the specification conditions, the optimum internal structure design will be considered.