Core

Solid State Diffusion Bonding

About solid state diffusion bonding

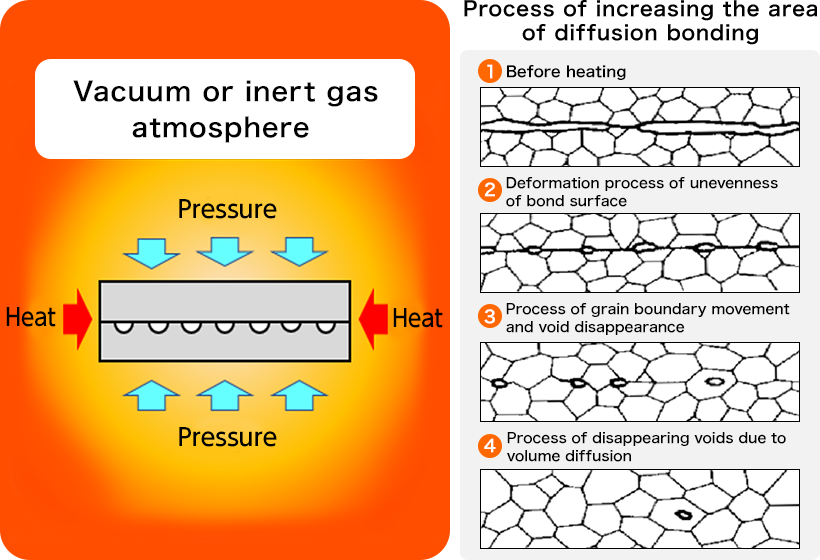

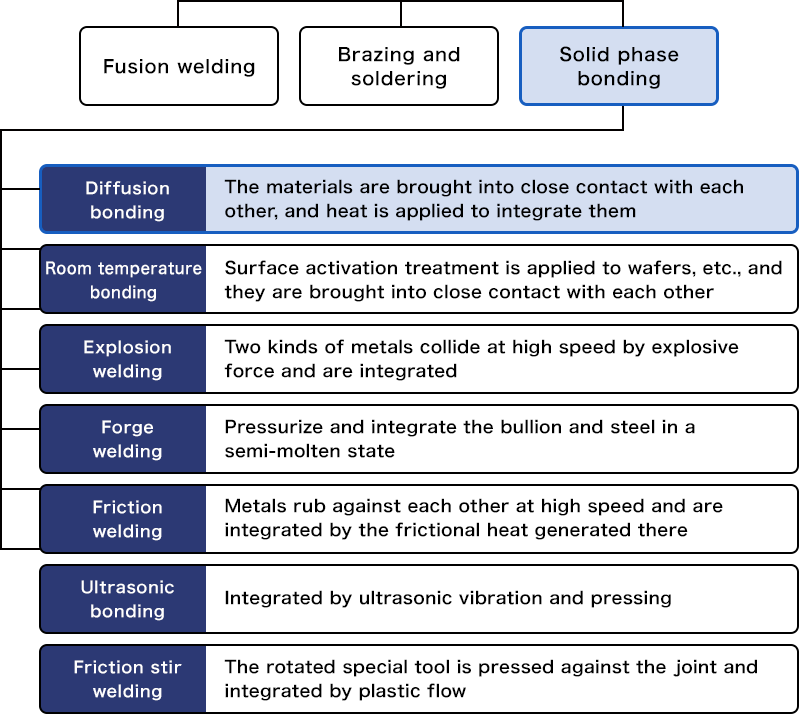

Diffusion bonding is a method of directly joining base materials to be joined, and is different from welding or brazing.

It is a method of bonding by heating and pressurizing the base material to promote the movement of atoms at the bonding interface.

By joining materials in a solid state without melting them, it is possible to create complex hollow 3D structures.

- Laminated joining of thin plates is possible

- Bonding force comparable to that of the base material can be obtained

- Complex hollow parts can be manufactured

- Precise bonding with small deformation is possible

- Different materials can be bonded

The process of solid-phase diffusion bonding has made it possible to fabricate fluidic devices with microchannel structures and devices with complex micro three-dimensional structures.

Our raison d'être and involvement with diffusion bonding

Industrial Applications of Diffusion Bonding

Diffusion bonding, a process technology developed in the late 1950s, was limited to applications in the nuclear, aerospace, and military fields.

WELCON has been working to make diffusion bonding technology suitable for mass production since before the company was founded in 2006. Emphasizing the principles, we have tried to confirm the process on actual machines as much as possible, rather than just using literature or calculation results. One of our strengths, "thermal one-stop," would not be possible without the accumulation of "examination and verification" from material analysis of joined products to mass production, inspection, and quality assurance. By continuing to accumulate this experience, we hope to further strengthen our strengths and meet the various challenges of a wide range of customers.

The following are some examples of fields in which our products and systems have been applied.

- Aerospace

- Chemical plants

- Printing machines

- Fuel cells

- Electronic devices

- Semiconductor Manufacturing Equipment

- Information and Communication / Antenna

- Automotive

- Molds

- Medical and inspection equipment

- Hydrogen stations

- Data servers

- Laser and LED cooling

- Food related equipment

We also have experience in other fields.